VFD cables (Variable Frequency Drive Cables) are essential components in modern motor control systems, especially in industrial applications. These cables play a vital role in improving motor efficiency, reducing electrical losses, and protecting systems from electromagnetic interference (EMI), making them indispensable in factories and production lines.

What Are VFD Cables?

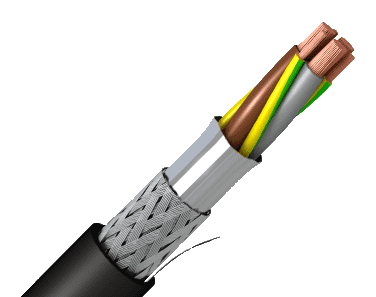

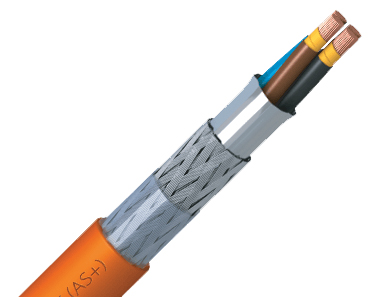

VFD cables are specially designed to connect Variable Frequency Drives (VFDs) to electric motors. They are engineered to withstand high voltage levels, fast PWM pulses, and elevated temperatures resulting from continuous operation. Additionally, they feature strong insulation and shielding to minimize electromagnetic interference.

Importance of VFD Cables in Industrial Systems

Motor Protection: Reduces failures caused by voltage spikes and fast switching pulses.

EMI Reduction: Protects nearby equipment from electrical noise.

System Efficiency: Enhances power transmission and minimizes energy losses.

Extended Equipment Lifespan: High-quality insulation and shielding improve durability.

Key Features of VFD Cables

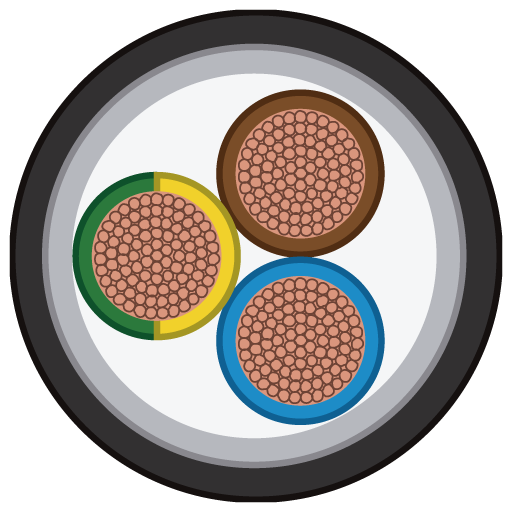

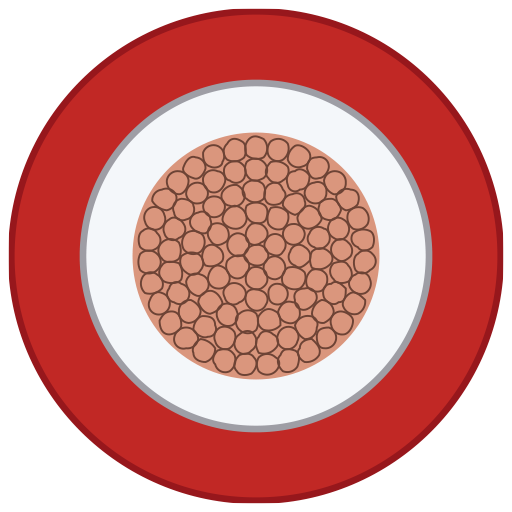

High-quality insulation resistant to heat and oils.

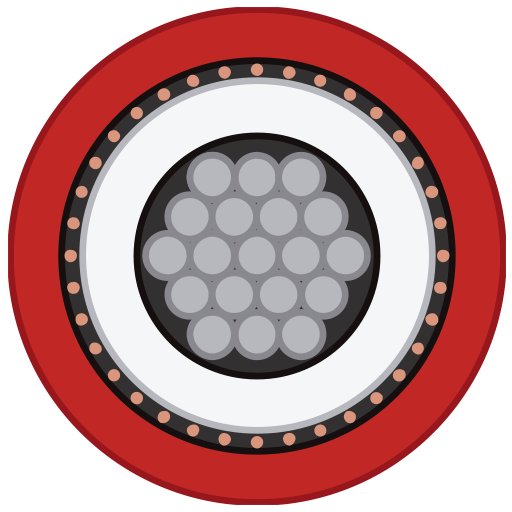

Copper or aluminum shielding to reduce EMI.

High flexibility for easy installation.

Excellent resistance to vibration and harsh environments.

Applications of VFD Cables

Industrial manufacturing plants.

HVAC and air conditioning systems.

Water and wastewater treatment plants.

Elevators and escalators.

Renewable energy systems.

How to Choose the Right VFD Cable

When selecting a VFD cable, consider:

Operating voltage and current.

Cable length.

Environmental conditions (temperature, humidity, oils).

Required shielding level.

Compliance with international standards.

The new generation of variable-speed drive (VDF) provide a series of advantages to the industry, but at the same time one of their main disadvantages is the emission of electromagnetic interference.

In order to limit the extent of this type of electromagnetic interference it is necessary to use equipment and cable with Electromagnetic Compatibility, known as EMC.

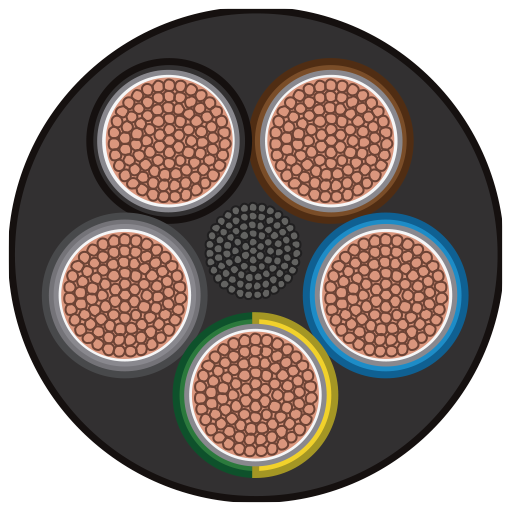

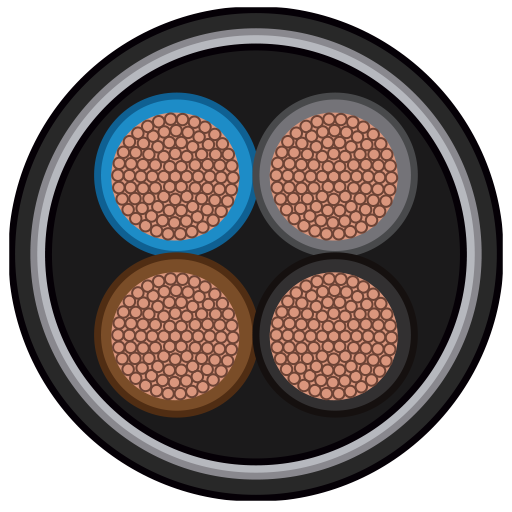

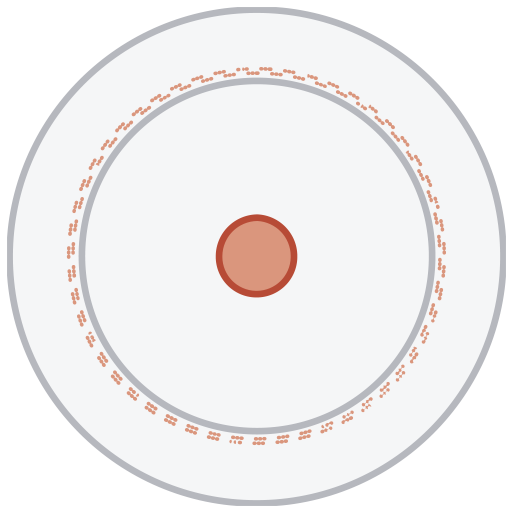

With regards to cable the necessary EMC is achieved by firstly ensuring a symmetrical distribution of the conductors. Secondly, a special protective screen is added to ensure the required EMC when variation-speed drives are used. This means a longer lifespan for the motor or pump being used.

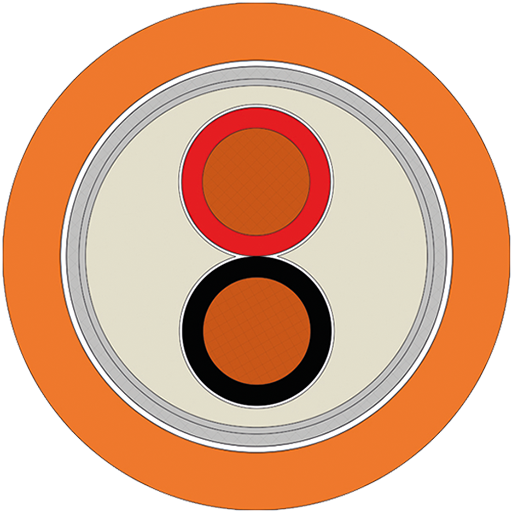

This cable has been specially designed for use in installations where it is necessary to limit the effects of Electromagnetic Interference (EMI), also know as Radio Frequency Interference (RFI).

The source of this kind of interference may be an object or device that carries changing electrical currents.

VFD cables are designed with three phase conductors plus grounding, and have a low smoke emitting and halogen free sheath.

They are flexible cables suitable for fixed installations.

VFD Cables

VFD Cables Solar Cables

Solar Cables Rubber Cables

Rubber Cables Pair Cables

Pair Cables Multi Core Cables

Multi Core Cables LSZH Cables

LSZH Cables Fire Resistent Cables

Fire Resistent Cables Fire Alarm Cable

Fire Alarm Cable Fiber Optic Cables

Fiber Optic Cables Data Cable

Data Cable Coaxial Cables

Coaxial Cables