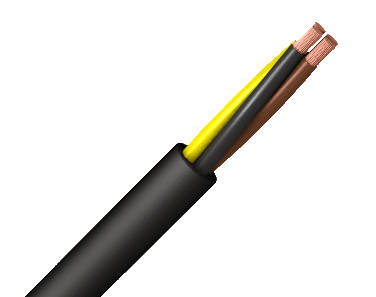

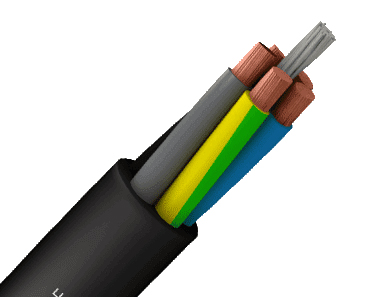

Rubber Cables are among the most widely used electrical cables in industrial and construction applications that require high flexibility, durability, and safety. Due to their ability to withstand harsh environments such as heat, moisture, oils, and mechanical stress, rubber cables are a preferred choice in many industries.

What Are Rubber Cables?

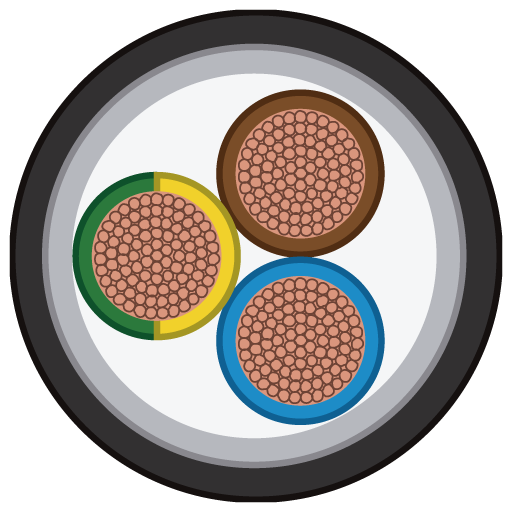

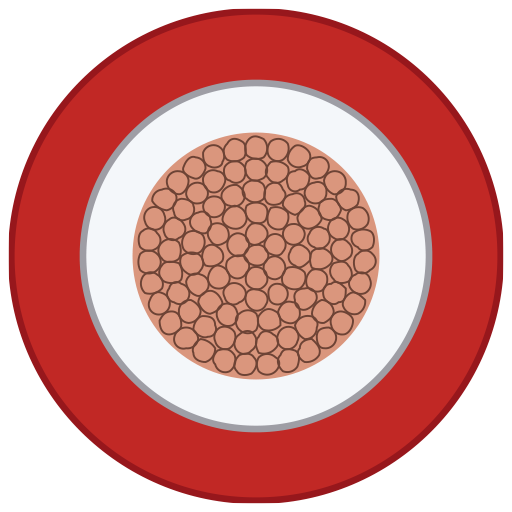

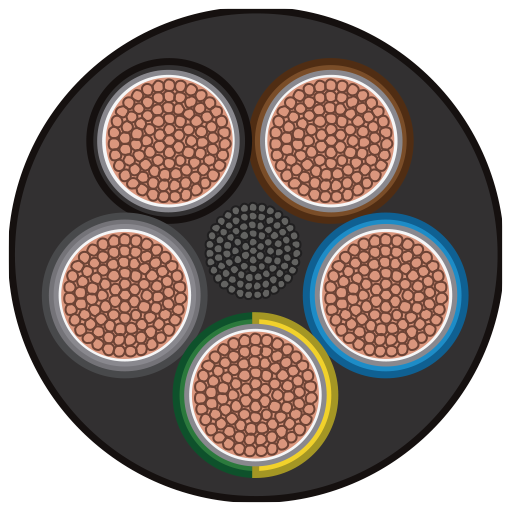

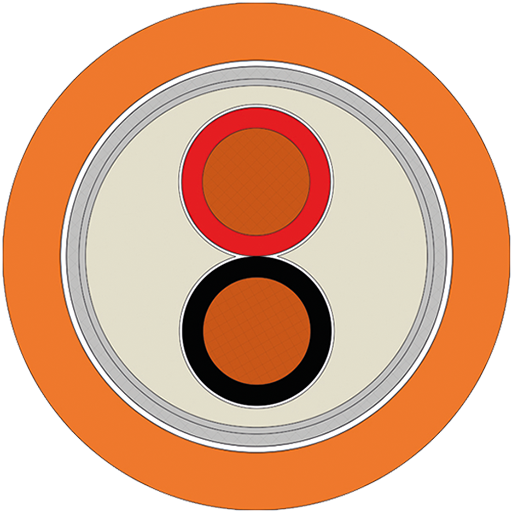

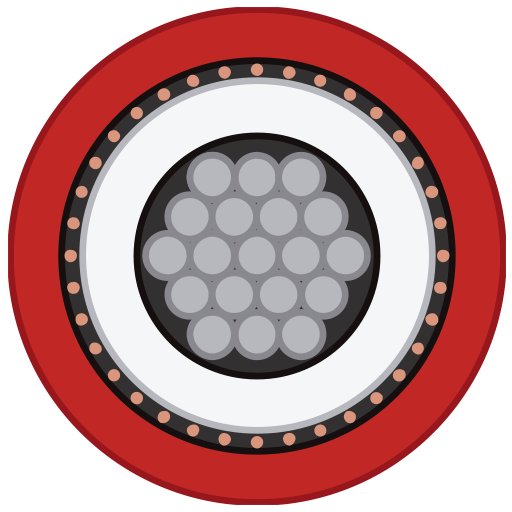

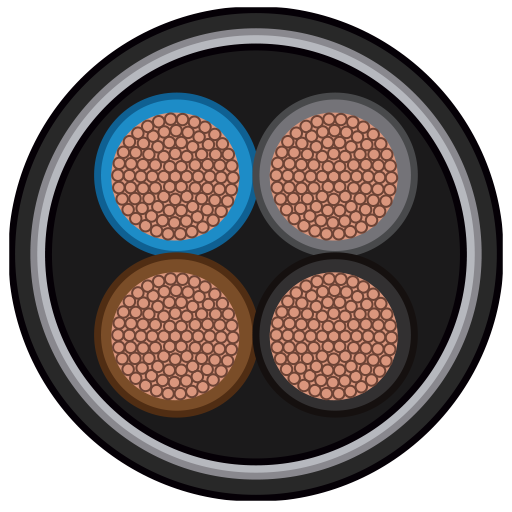

Rubber cables are electrical cables insulated with high-quality rubber compounds such as EPR or Neoprene. They offer excellent flexibility and resistance to mechanical impact, making them ideal for applications where standard PVC cables are not suitable.

Importance of Rubber Cables in Industrial Applications

Withstand harsh operating conditions.

High flexibility for continuous movement.

Enhanced safety against cracking and damage.

Long service life even under heavy-duty use.

Key Features of High-Quality Rubber Cables

Excellent heat resistance up to 90°C or higher.

High resistance to oils, grease, and chemicals.

Superior flexibility even at low temperatures.

Strong resistance to vibration and mechanical stress.

Compliance with international standards.

Applications of Rubber Cables

Construction and building sites.

Industrial machinery and equipment.

Power stations and generators.

Cranes and hoists.

Mobile and temporary power systems.

How to Choose the Right Rubber Cable

When selecting a rubber cable, consider:

Operating voltage and current.

Number of cores and cross-sectional area.

Type of rubber insulation.

Environmental conditions (heat, oil, movement).

Compliance with certified standards.

VFD Cables

VFD Cables Solar Cables

Solar Cables Rubber Cables

Rubber Cables Pair Cables

Pair Cables Multi Core Cables

Multi Core Cables LSZH Cables

LSZH Cables Fire Resistent Cables

Fire Resistent Cables Fire Alarm Cable

Fire Alarm Cable Fiber Optic Cables

Fiber Optic Cables Data Cable

Data Cable Coaxial Cables

Coaxial Cables